ECLIPSE® IS ON THE RISE

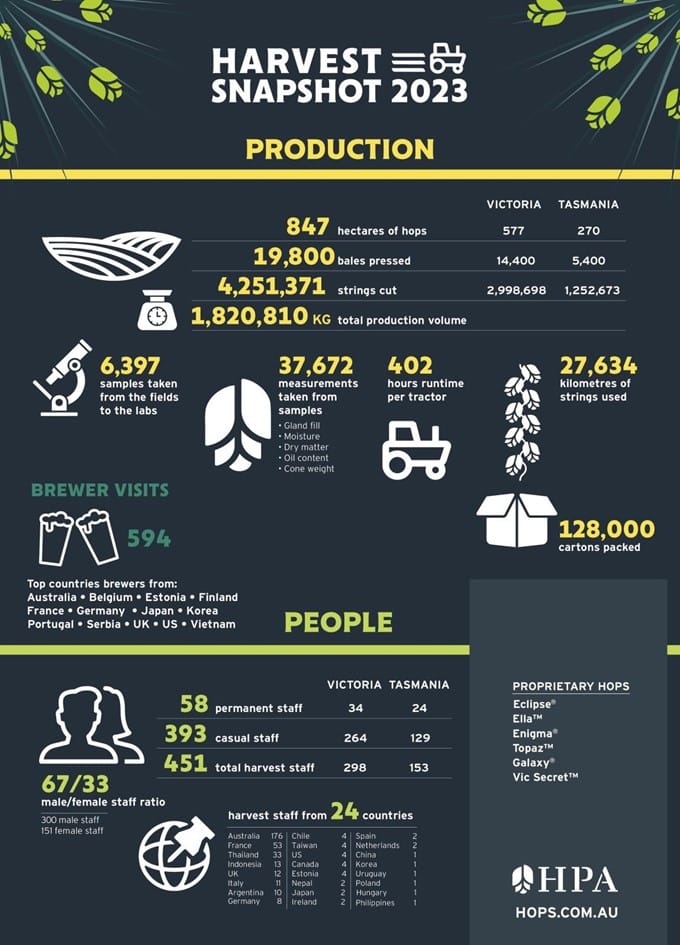

Hop Products Australia (HPA) have completed the 2023 hop harvest. We picked 847 hectares across Victoria and Tasmania, which resulted in 1,821 tonnes of hops. This was a 37-hectare (4.5%) net increase and a 164 tonne (9.9%) net increase year-on-year across six proprietary varieties – Eclipse®, EIIaTM, Enigma®, Galaxy®, Topazim and Vic SecretlM – as well as Cascade. This year’s oil content came in equal or above the 5-year average for all proprietary hops, with a particularly strong showing from Eclipse® that should lead to an exceptional year of performance in beer.

The final hectares of our Victorian expansion were scheduled to reach commercial maturity this season but were significantly impacted by a third consecutive La Nina weather pattern. Below average temperatures and above average rainfall early in the growing season initially slowed plant growth and caused localized flooding in Victoria towards the end of spring. Despite the adverse conditions we were able to modify our calendar of inputs accordingly, with above average temperatures and below average rainfall in summer aiding cone maturation.

Our Victorian and Tasmanian growing regions also experienced record low levels of solar radiation for the fourth consecutive year, particularly from October to November. This remains an area of interest since sunlight drives photosynthesis, and it’s possible this could be affecting production volume.

The year-on-year increases in Galaxy®, Vic SecretlM and Eclipse® are the result of our Victorian expansion, with second- and third-year plants reaching commercial maturity. These increases were somewhat lowered on account of adverse seasonal conditions that also significantly impacted

Ella’TM, Enigma® and Cascade. This bodes well for crop 2024 which has a more favourable long-range weather outlook. The year-on-year increase in Topaz directly correlates to the percentage of crop 2022 that was lost to hail damage.

| Production Volume (Metric Tonnes) | Year-on-Year Variation | |

|---|---|---|

| Galaxy® | 1,096 | +8,8% |

| Vic SecretlM | 320 | +10,3% |

| Eclipse® | 161 | +70,0% |

| EllaTM | 87 | -10,1% |

| Enigma® | 78 | -9,6% |

| Topazim | 60 | +9,2% |

| Cascade | 18 | -29,7% |

| Total | 1,821 | +9,9% |

Note: measurements calculated on raw hop quantities.

A portion of this year’s crop will be reserved for commissioning our new production facility in Victoria. The modern equipment will facilitate the centralization of every bale pressed from crop 2024 onwards, creating the opportunity for a whole-of-crop approach to blending that will ensure optimal outcomes for each of our Aussie hops. The temperature-controlled pellet plant and form, fill and seal packaging line will produce in excess of 50 tonnes of pellets per day. This will allow us to double our current processing capacity while retaining a higher percentage of essential oils in the finished pellets at a lower average Hop Storage Index (HSI). This means brewers can expect an overall increase in quality and a reduced spread of analytical data across lots, which will translate to more consistent performance in beer.

Impact in beer is expected to remain strong, with this year’s average oil content coming in equal or above the 5-year average for all proprietary hops. The two star performers were Eclipse° with a strong showing of oil content that should lead to an exceptional year of impact in beer, and Galaxy°with both oils and alphas above the long-term average ensuring high quality outcomes for our most popular hop. These results indicate that our current farming practices are capable of producing consistently high-quality hops so brewers can make consistently high-quality beer.

| OIL CONTENT | ALPHA ACIDS |

|---|---|

|  |

Note: measurements calculated on raw hop quantities. Processed hop pellets will show reduced values.

As the country’s largest hop grower, HPA is focused on a sustainable future of quality beer. This means a successful harvest is about more than production volume and oil content. The influx of people from overseas looking for seasonal work was a great relief this year. We saw a significant increase in the quantity and quality of applications, many of which had hop harvest or farm-related experience.

To protect our team we have increased our focus on safety over the past few years, which has led to a decline in our lost time injury (LTI) frequency. Continued improvements to our safe work practices, induction and training, as well as investment in safety management software with real-time reporting capabilities has made this our safest harvest in recent history.

Continuing our commitment to the UN global compact, we also completed the initial Life Cycle Analysis (LCA) of our business to identify key areas and realistic targets to support the implementation of low emission practices that will improve our brewing customers indirect emissions moving forward.

After three years of keeping our farms closed to visitors, we were excited to welcome more than 590 local and international brewing customers on farm this year. Together, we followed our Aussie hops from the gardens through each stage of the production process, plus freedom to roam our world class breeding gardens. It was one big celebration of the close ties between Aussie agriculture and Aussie

beer.

Even though the hop and brewing world is going through a significant realignment of supply and demand as brewers endure some of the toughest years on record, the outlook for Aussie hops remains steady and crop 2023 is heavily contracted. The importance we place on responsible contracting will allow us to meet all commitments, with a very limited amount available on the spot market. Brewers are encouraged to proactively communicate their Aussie hop requirements to our sales team and enter into rolling forward contracts for supply security.

Tim Lord

Managing Director

May 2023

Leave A Comment