2020 NEW SEASON MALT GUIDE

We make great malt, but that wouldn’t be possible if it wasn’t for the dedication and skill of the British farmers who provide us with the best malting barley that they can grow. With the combine harvesters put away and 100% of our barley needs safely laid down in our stores, we can report that harvest 2019 has been a bumper year.

As the new crop is making its way through the malthouse we want to make sure that you’re prepared for any changes that might be thrown up as you transition from crop 2018 to crop 2019. That’s why we’ve worked with our master maltsters and brewers to prepare this handy guide to the season changeover. This guide is also particularly useful when you change over base malt generally.

HARVEST 2019

The 2019 growing season didn’t provide us with the same long, hot, dry summer that we ‘enjoyed’ in 2018, and for that the crops were ultimately grateful, and although it will go down as a more normal year meteorologically, it still provided its challenges!

Winter barley is planted in September & October, and although the drought had broken, the soils were still dry and rainfall continued below average through the winter months. Whilst it would have been nice to have some wetter weather, the dry did encourage the plants to put down good roots in the search for moisture, which was good news given the unusually warm February.

Spring barley planting was completed in March & April which is the ideal time, and then there was a nervous wait for the weather – with memories of the previous year’s drought still fresh in our minds, everyone was hoping for rain…and finally it came, when it did its best to make up for lost time with a miserable May. The rest of the growing season was relatively calm after that, apart from the record- breaking one day heatwave when temperatures exceeded 40°C in East Anglia, and the winter barley harvest passed off without incident, though the spring barley harvest, especially in Scotland, was delayed by a very wet August.

So what was the upshot of all that? Well, pretty good, actually! Yields were generally good, as was the quality, with one exception – Maris Otter. Give it its due, it doesn’t do badly for a variety now entering its 55th crop year, but this year proved hard on it! The rains came too late in May for some land, it seems, and someof the crop has been lost through poor quality, which is not ideal as demand continues to grow. However, being located in the heart of Maris Otter country in North Norfolk, with a loyal band of experienced malting barley growers all around us means thatwe will manage tosecure our needs for 2020!

In terms of pricing, feed crops did well which has brought the overall grain market down, so we are able to offer a price reduction on 2019 pricing going in to 2020.

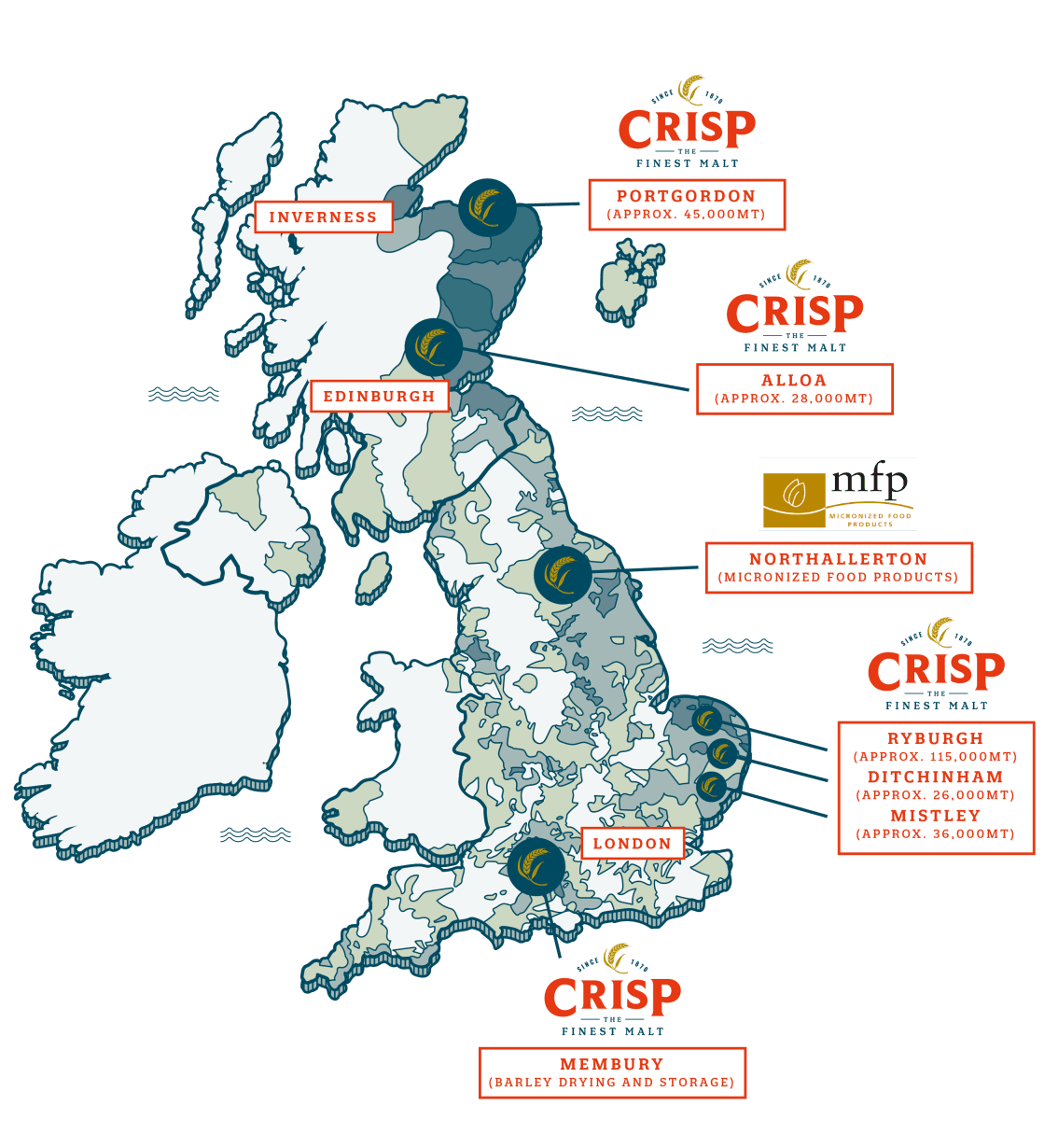

Crisp operates 3 direct-farmer contract groups

- Local partnerships with 280 growers

- Norfolk, South West England & Scotland

- Offering a range of contract types

- Enables sourcing of correct varieties at the correct qualities required (weather permitting!)

WHAT’S CHANGED?

Our lives as maltsters, brewers and distillers would be much simpler if the barley didn’t change from year to year. While we do our utmost to iron out inconsistencies from crop to crop, there are always going to be subtle changes in the biology of the plant which can affect the way the malt behaves in the mashtun. We’ve written up some of the changes that we see in the 2019 crop barley and how they might affect your brewhouse practices.

CORN SIZE

The corn size can vary depending on the variety and weather. We are looking for plump grains that will take up water well during steeping and give good levels of extract. At Crisp we remove the small corns (that which passes through a 2.25mm screen) and this ensures we get an even malting of the batch. If the corn size distribution has changed it means the milling might also change. On the bagging line we are constantly checking the grist fractions by performing a sieve analysis. If you mill your own malt then this is a simple test that you can also perform. Too much milling and you could end up with higher extract, over attenuated beers, but a stuck mash. Too little milling and it will be lower extract and you will be leaving sugars behind in the grain. Take a look at our quick guide on how to optimise your grist.

Cornsize seen here:

FRIABILITY

Friability is a measure of how well modified the malt is and how easily it will mill. We often see malts from the continent and some part of the UK with poor friability (around 80%). We would ideally want friability to be greater than 90%. This is an indication of good malting practice. A change in friability means your mill setting may need to be adjusted. As mentioned above, we recommend a simple grist analysis tocheck yourmilling is optimised.

NITROGEN/PROTEIN LEVEL

The barley plant can put its energy into making starch or protein, more commonly referred to in the UK by its base element nitrogen. When the nitrogen goes up, the starch goes down and we lose extract. There is a very specific sweet spot for ale and lager malts for nitrogen content, namely 1.35-1.65% TN for ale malt and up to 1.75% for lager malt.

A good practice at the changeover in crop years is to optimise your kettle finings. This will ensure you’re taking enough protein out of the boil which will help with yeast health and also ensure bright, shelf-stable beers. Contact your finings supplier for advice onperformingthesimple finings optimisationtests.

Yeast growth and viability can vary depending on the total nitrogen of the crop affecting the Free Amino Nitrogen (FAN) content and make-up. If yeast growth and viability are adversely affected, indicated by sluggish fermentations, the only solution is to add yeast nutrients and increase pitching rates. Some yeast strains are moresensitive toFAN thanothers.

EXTRACT

As mentioned above, the extract may vary due to the nitrogen content of the malt. We work very hard to ensure a consistent extract from season to season and throughout the year. It’s always good to read your certificate of analysis to check if the extract has changed. You should always work with the “AS IS” extract not the “DRY” extract for making gravity calculations. If you’re unsure of working out target gravitywe can providea handy calculatorspreadsheet.

DIASTATIC POWER (DP)/ ENZYME POTENTIAL

The diastatic power is a measure of some of the enzyme activity in the grain; the higher the DP the higher the conversion rate from starch to fermentable sugar. The determination of gravities (thus ABV) is an enzyme driven process and is affected by enzyme potential, mash time, temperature and thickness. The enzymic potential can be seasonal and will affect the formation of different sugars, the higher the number of complex sugars the slower the beer will ferment towards the final gravity. On the other hand, too many simple sugars will cause over-attenuation and higher than expected alcohol content. The way to solve these issues is to use the mash temperature and thicknesstocontrolfermentable sugars;

- Thinmash/lowtemperature(63’C) willencourage simple sugarstobe formed

- Thick/high temperature (68’C) will encourage more complex sugars to be formed

We would always recommend carrying out a simple starch test using iodine to check that you have full conversion of starch into sugar. As soon as this conversion is completeyou can starttorun off.

GRIST SHAKE TEST GUIDE

At Crisp we monitor the grist fractions on every single batch of crushed malt that passes through our mill. It is only by doing this, that we can optimise the balance between run-off and extract for our brewers and distillers. We do this by using a simple grist box as shown. If you mill your own malt then this is an essential test to perform every few weeks and especially when moving from one crop year to another, or from one base malt to another.

MILLING OPTIMISATION

These are the fractions we work to at Crisp for crushed malt, but if you operate a lauter tun then you may wish to mill a touch finer.

Regular maintenance of your mill, including monitoring of the wear on the roll pack will ensure consistent mill performance.

If you’re in any doubt about your milling performance, then please speak to our technical team who will be happy to assist.

9.

TYPICAL IOB ANALYSIS

GET IN TOUCH WITH OUR TEAM OF MALTSTERS

If you have a desire to dig more deeply into any of the technical aspects of this guide then please get in touch.

Leave A Comment